About us

One stop shop. From crystals Growth to optical Assembly

Raicol Crystals is a world leading manufacturer of high-quality nonlinear optical crystals and electro-optical components for laser systems. We specialize in the manufacture of customized products for the medical, defense, industrial, and aerospace industries.

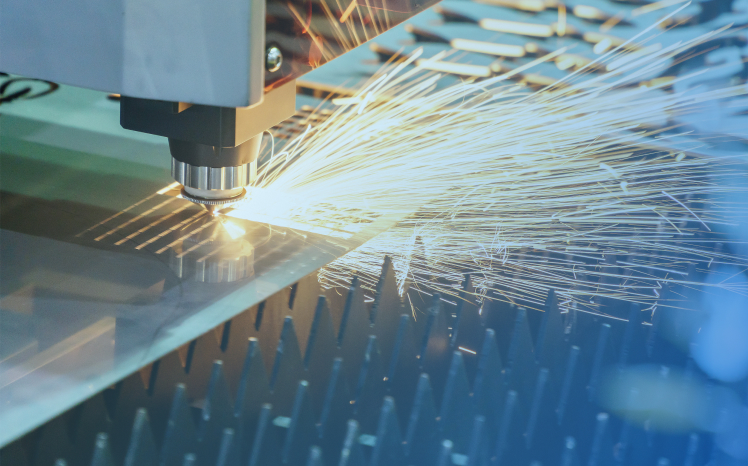

Raicol Manufacture

Raicol manufacture a variety of different crystals, including RTP, KTP, LBO, BBO, PPKTP,PPSLT, PPLN and CLBO.

Our cutting-edge manufacturing facility is a one-stop-shop, consisting of all the equipment required for high quality production, including proprietary growth systems, cutting and polishing machines, X-ray measurement systems, clean rooms, optical assembly equipment, state-of-the-art testing stations, and a coating facility.

Together with our unparalleled expertise in the field, this equipment allows us to ensure every one of our products is of the highest quality and reliability. Here at Raicol, we maintain careful control over crystal growth, and apply stringent quality control methodologies at every stage of the fabrication process, enabling us to receive ISO 9001 certification.

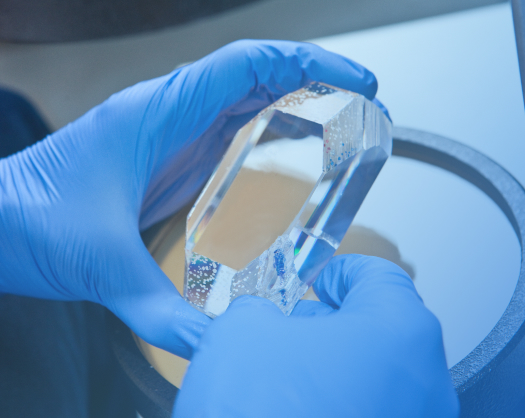

Crystal Growth

Raicol’s crystal growth department is one of the largest in the West. It houses over 200 crystal growth stations, designed specifically to manufacture of the best quality RTP, HGTR, KTP, KTP-OPO, LBO, and BBO crystals available on the market.

The crystal growth team has grown many thousands of crystals between them, with the combined experience of every team member amounting to hundreds of years.

Optical Fabrication

Raicol are leaders in the industry when it comes to optical fabrication. We were the first to provide super polished crystals with low Scratch-Dig, which then became the industry standard. Now, we are leading the way with the further development of crystals that have only a few Angstroms in roughness, and a Scratch-Dig approaching 0-0.

Our optical fabrication production line is designed to produce repeatable high-end crystals, using the latest fabrication equipment. This enables us to meet all of our customer’s demands, including exact crystal dicing, grinding, and polishing.

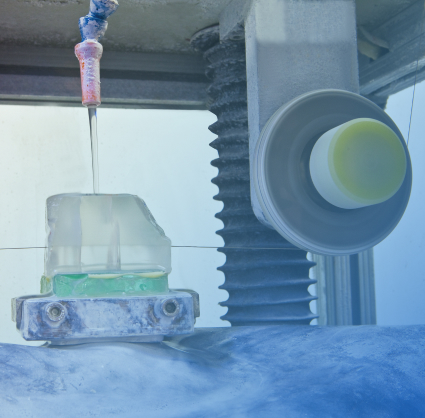

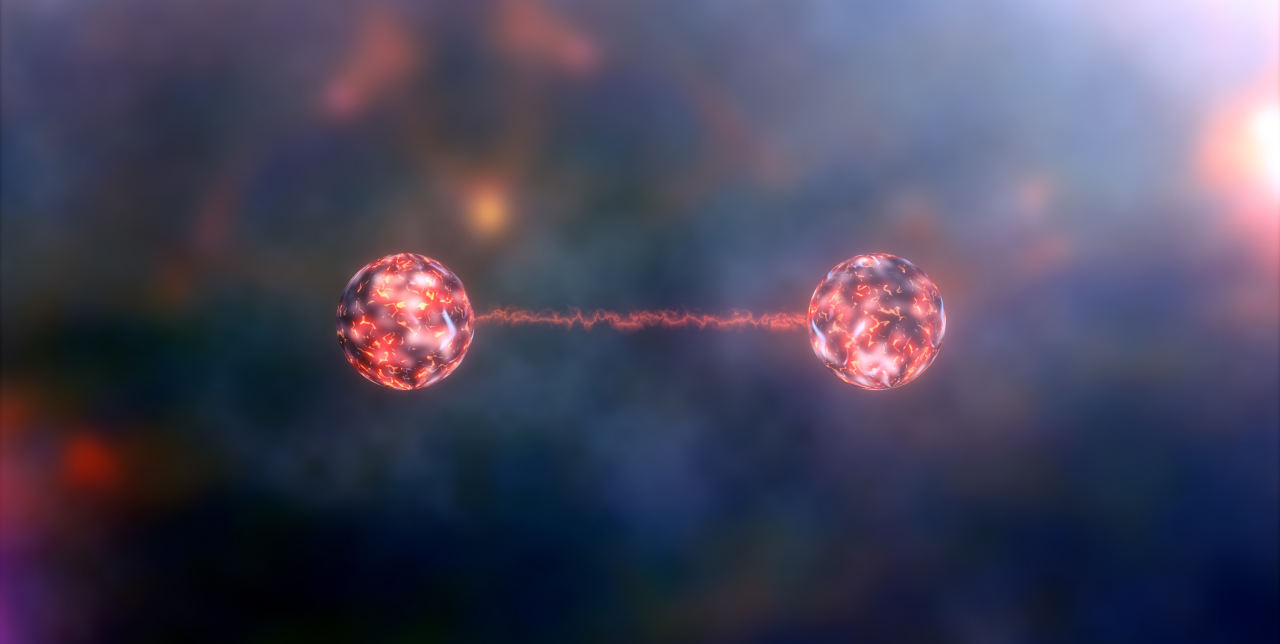

Periodic Poling

We are the sole large-scale producers of bulk PPKTP. When it comes to PPKTP and PPLN, our crystals are of the highest quality possible, thanks to our highly experienced team, who are constantly developing new capabilities to meet customer requirements.

Our periodically poled products are used for almost every quantum application, and all major research facilities work with PPKTP. New periodically poled products are designed for our clients every day, and recently our novel aPKTP crystals designed for new and exciting features!

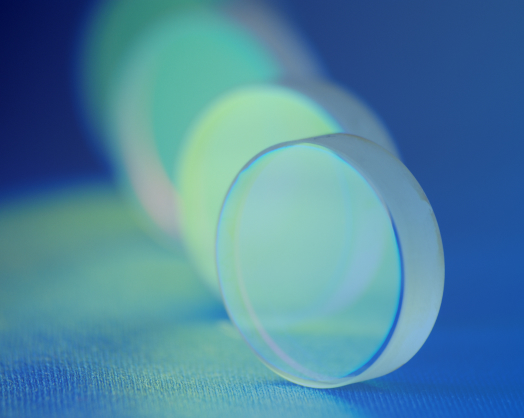

Optical Coating

Our coating facilities allow in-house AR, DBAR and BBAR coatings, with a relatively large throughput to maintain homogeneity. Our team of professionals are able to design and produce new coating types for different wavelengths and applications, Our team of professionals.

Assembly And Inspection

Our state-of-the-art in-house testing capabilities include some of the most accurate testing equipment possible, ensuring the highest quality results before shipping our products to clients.

Our testing capabilities include:

- Low and high-power absorption tests up to sub-ppm levels

- Laser damage threshold measurements

- Roughness and flatness measurements with sub-Angstrom accuracy, using state of the art interferometers

- XRD measurements

- Wavefront distortion tests

- Reflectance and transmission measurements

- Microscopy quality measurements

- Temperature, environment, and lifetime stability tests

Since 1995

Raicol Crystals offers a one-stop-shop for high end products as well as special customize solutions for customers success.