A growing number of companies are switching to industrial RTP crystals for electro-optic Pockels cells

In the past year, there has been a growing trend for industrial companies to switch their traditional Pockels cell (PC) components, mostly KD*P, to industrial RTP Crystal.

The excellent EO properties of RTP, its simple setup and configuration, along with its attractive pricing, makes it a great alternative for current PC solutions. Industrial RTP enables increased ROI for a project, by saving time and money for the laser production line and across the product’s lifetime.

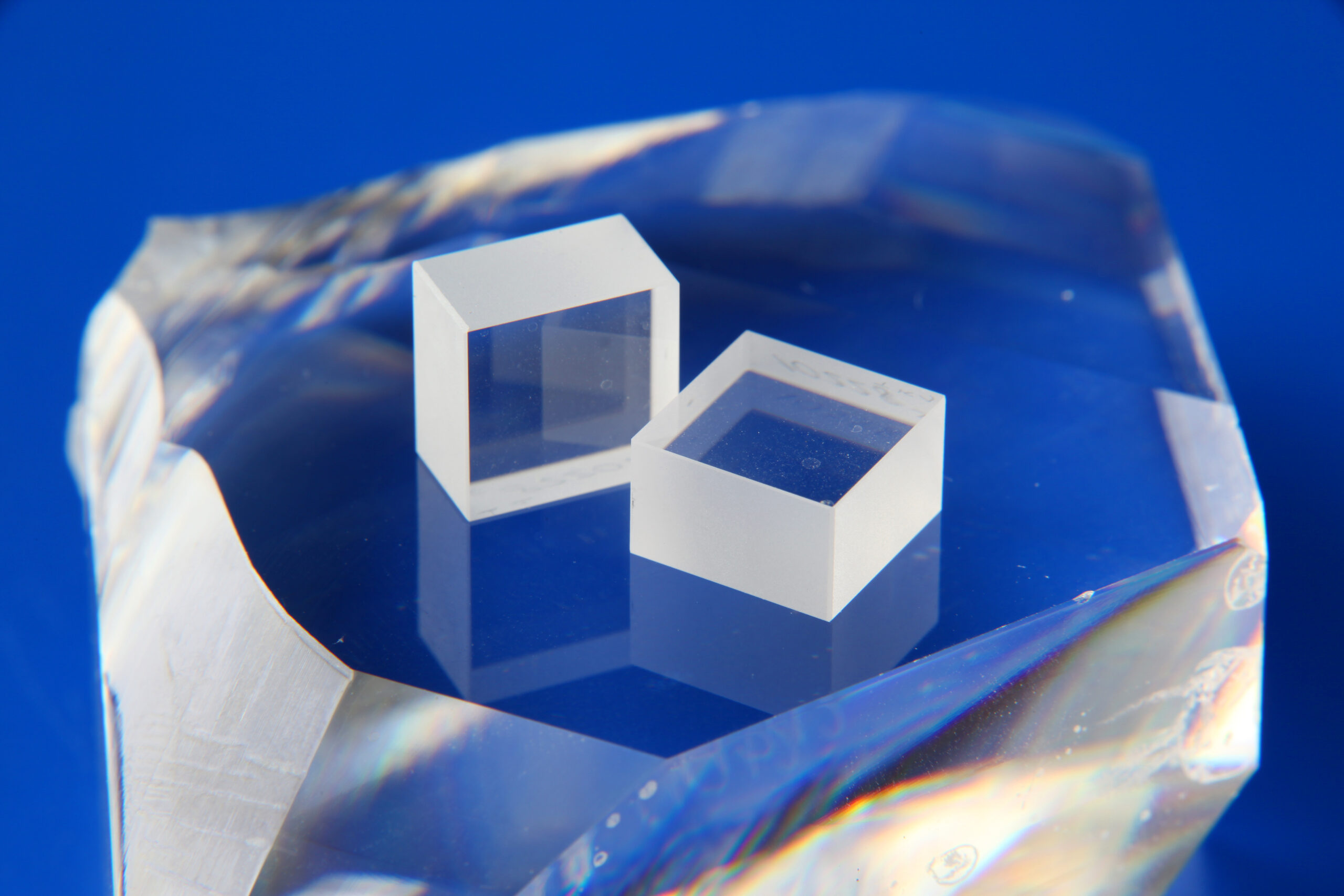

About RTP

RTP belongs to the KTP Crystal family. The outstanding electro-optical properties of RTP, together with its high damage threshold, enable its use in high-end laser applications, it is ideal for use in applications that require advanced characteristics, such as being non-hygroscopic, having high thermal stability, and for higher-repetition rates.

Raicol’s RTP PC is widely recognized for the following features:

- Higher laser damage threshold

- Non-hygroscopic material

- Low absorption losses

- No acoustic ringing (up to at least 200kHz)

- Stability over a wide temperature range (10ºC –50ºC)

While providing many advantages over existing solutions, the advanced properties of RTP came with a price tag that prevented its widespread use for industrial applications.

Raicol’s new industrial RTP

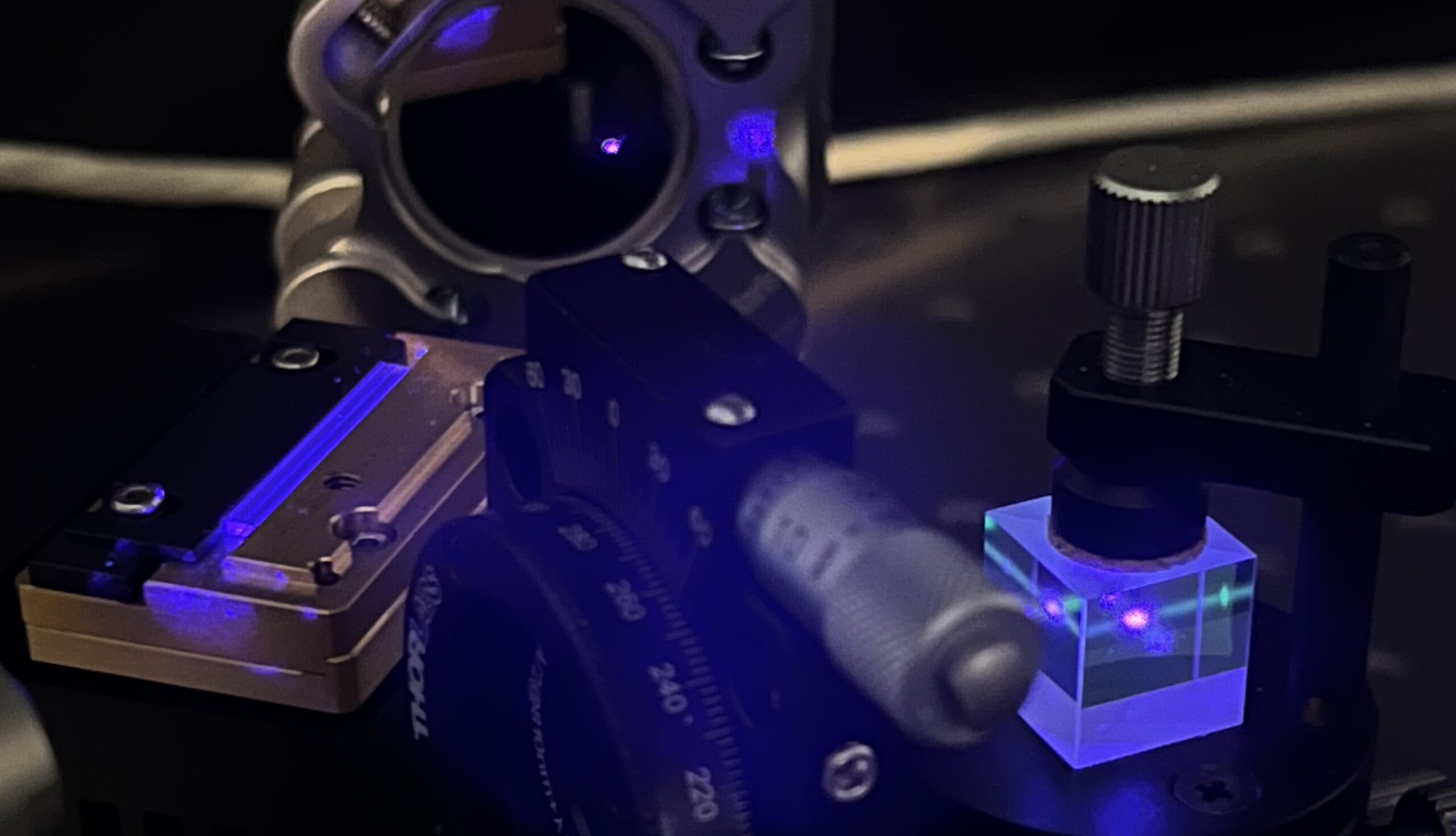

Raicol’s new iRTP PC is the first product that brings the advantages of RTP to the EO mass market. The modified iRTP PC version of Raicol’s RTP is especially designed for the needs of the industrial laser market. Raicol’s iRTP PC is a standard off-the-shelf RTP PC that offers high performance EO cells at the price level of standard industry PCs.

iRTP vs KD*P Benefits

- Improved thermal stability – iRTP has thermal stability over a wide range of temperatures, eliminating the need for thermal stabilization, thus eliminating the need for an oven or thermal control systems.

- Reduce laser initiation time – RTP’s high thermal stability reduces laser stabilization and start up times, as well as the overall system initiation time.

- Simple alignment – iRTP requires only 1D alignment to reach an optimum extinction ratio, in comparison to KD*P, which requires 3D axis control-significantly complexifying the alignment process.

- Environmental stability- iRTP is a non-hygroscopic material with a temperature compensation design that allows it to function in non-controlled environments with a variety of temperatures and humidity levels.

- Mechanical robustness and stability – iRTP’s requirement for only 1D alignment means that the iRTP package and mount has a simple and more mechanically stable design. The working parameters do not change throughout the laser’s lifetime, or during temperature changes, hence, requires little to no calibration over time.

- Small size – The size and footprint of iRTP is much smaller compared to similar KD*P, due to a reduction in assembly, alignment, and temperature control components.

- High repetition rate – iRTP supports a repetition rate up to 200 kHz.

- Standard Pockels cell assembly – iRTP is an off-the-shelf product with standard industry EO cell specifications.

- High damage threshold – iRTPs high damage threshold enables its use for high power lasers.

Do you have a question? Our experts will be happy to hear from you and advise you on the best product for you. Contact Us.

Have you already subscribed to our YouTube channel? Don’t miss out—subscribe now for exclusive content and updates from our company.